DECCAN MECHANICAL AND CHEMICAL INDS.P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to DECCAN MECHANICAL AND CHEMICAL INDS.P.LTD.

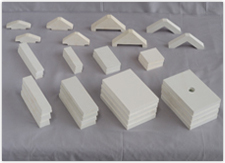

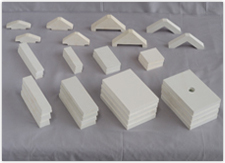

Cast Basalt Liners

After selective quarrying the rock is melted at a temperature of around 1500 degree C and cast into molds or spun into cylinders. The castings so produced are then subjected to heat treatment cycles in special kilns to produce re-crystallized basalt. The product thus produced inherits inertness of parent materials. Its microcrystalline, non-porous texture being denser and more homogenous than raw basalt, it acquires exceptionally high abrasion resistance.

Ceramic Lined Equipments

DEMECH manufactures a wide range of high alumina ceramic liners such as tiles, special shapes and pipe sections which have high alumina content and wear protection properties. These liners are bonded on to steel surfaces and are extremely effective for prevention of wear and tear due to high particle velocity, impingement, abrasion and impact. They are extensively used for lining of equipment prone to severe wear in core sector industries such as cement, steel, power.

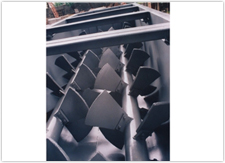

Chain Conveyor

Slow moving chains in these conveyors influence the material to move gently through a closed duct in a horizontal or even in steeply inclined profiles. These can handle virtually any type of bulk material in an environmentally safe way due to its dust-tight and spill proof, totally enclosed construction. These conveyors are heavy duty and of rugged construction.

Chromax Plates

CHROMAX wear plate by DEMECH is a composite plate, manufactured by a unique process in which a uniform layer of highly wear resistant carbides is deposited on a carbon steel base. Very hard carbides are suspended in a tough wear resistant matrix. It is the concentration & uniform distribution of carbide structure that gives CHROMAX Wear Plate its unique wear resistant & life prolonging characteristics.

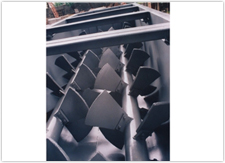

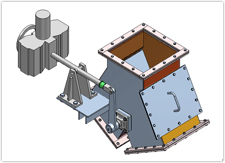

Paddle Mixer And Mixer Conveyor And Ash Mixer

DEMECH Mixer Conveyors find applications in many industries. This equipment is the perfect solution for pollution control as it effectively blends dust - recovered from ESP, Mechanical collectors, bag houses, Silos etc.- with various liquids, thus allowing transport but effectively controlling the particulate matter escaping into the air.

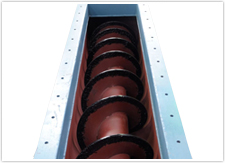

Screw Conveyor

Screw conveyors are used to convey the material continuously with the help of a rotating helical screw blade (known as flights) by shear and tumbling effect inside a U shaped trough or a round tube. They are generally used for handling fines of coal, crushed material, powders, cement, chemicals etc.

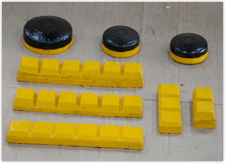

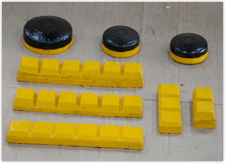

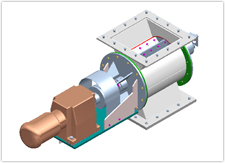

Rotary Air Lock Valves

DEMECH provides a complete range of Rotary Airlocks suitable for air lock applications ranging from gravity discharge of filters, rotary valves, cyclone dust collectors, and rotary airlock storage devices to precision feeders for dilute phase and continuous dense phase pneumatic conveying systems.

Double Flap And Cone Valve

Double Cone / Flap valves are used for controlled feeding as well as achieving air lock sealing. These valves consist of two independent Cone / Flap valves mounted one upon other with their opening and closing alternated and synchronized to ensure that only one valve opens at a time.

Gravimetric Feeders

Demech has entered into technical collaboration with Hitachi Power Europe GmbH (HPE), Duisburg, Germany; to manufacture Gravimetric Coal Feeders. This gives Demech the unique advantage to supply Gravimetric Coal Feeders using the proven and reliable designs of Hitachi Power Europe GmbH.

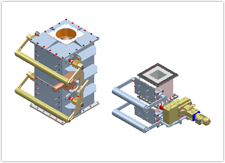

Bottom Ash Handling System

DEMECH provides variety of systems to handle Bottom Ash or Bed Ash generated by the solid fuel fired boilers. The system has to be selected based on many factors like type of boiler, size of boiler, amount of Bottom ash generated, method of final handling etc. Factors like availability of other resources like water, land etc. also need to be considered while selecting the system. DEMECH can supply following systems

Hyjector (Jet Pump)

69078.jpg)

DEMECH Hyjector is designed for the best efficiency and long life. The Nozzle &Ventury throat is designed to suit the application. The slurry can be pumped to a discharge pressure of 30 meters. The main advantage of this equipment is it can operate when the suction is inadequate and chances of air being sucked is high where a normal pump can never operate.

Wet Ash Handling Systems

Description / Specification of Wet Ash Handling Systems

We are involved in offering a wide range of Wet Ash Handling Systems to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Wet Ash Handling Systems. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Feeder Ejector

DEMECH Feeder Ejector can be directly mounted below hopper without any feed elbow. DEMECH feeder ejectors are highly efficient and can create ash slurry of concentration up to 35% to 40% resulting in low water consumption. Assembly is made in four major parts. Discharging angle 450 and 700 are available to suit layout. The water pressure required is about 4 kg/cm². They are available with two capacity ratings and sizes i.e. 30 TPH & 60 TPH and 6"×4"×8" & 8"×4"×8" respectively.

Ash Disposal Systems

The ash produced in big boilers is so high in quantity, that to utilize it completely converting into useful product is not always possible. In such conditions ash is required to be dumped in ash pond / ash pits which are usually far away from the plant area. The most efficient method of disposing ash in such cases is by pumping it in form of slurry through cast basalt pipes.

Pneumatic Handling Systems (Ash And Nonash)

69082.jpg)

Description / Specification of Pneumatic Handling Systems (Ash And Nonash)

We are involved in offering a wide range of Pneumatic Handling Systems (Ash And Nonash) to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Pneumatic Handling Systems (Ash And Nonash). Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

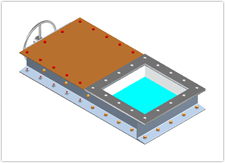

Industrial Dampers

Description / Specification of Industrial Dampers

We are involved in offering a wide range of Industrial Dampers to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Industrial Dampers. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.